Products not found

The Series 4000 Capsuhelic® Differential Pressure Gage is designed to give fast, accurate indication of differential pressures. The gage may be used as a readout device when measuring flowing fluids, pressure drop across filters, liquid levels in storage tanks and many other applications involving pressure, vacuum or differential pressure. The pressure being measured is held within a capsule which is an integral part of the gage. This containment of the pressure permits the use of the gage on system pressures of up to 500 psig, even when differentials to be read are less than 0.1 in w.c.

Retail price from $772.7

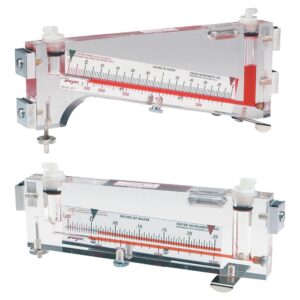

Designed to measure air velocity, static pressure, vacuum or differential pressure, where the additional range of the 400 Series gages is not required. Series 100 Gages offer superb accuracy combined with portability. The Dwyer® Durablock® precision machined solid acrylic plastic construction, the wells and inclined bore are machined to tolerances of ±.0002″.

Retail price from $111,75

The Series PTGD Differential Pressure Piston-Type Gage can be used to measure the pressure drop across filters, strainers, pump performance testing, and heat exchanger pressure drop monitoring. Its simple, rugged design possesses weather and corrosion resistant gage front with a shatter resistant lens. The Series PTGD contains a piston-sensing element which provides different differential pressure ranges with full-scale accuracies of ±2%. Constructed with aluminum or 316SS and available with two 1/4″ female NPT end connections, the Series PTGD provides over-range protection rated to 3000 psig (200 bar) or 6000 psig (400 bar) depending on model. Standard models come with in-line connections. Back or bottom connections are also available.

Retail price from $254.6

The Series PFG2 Process Filter Gage is designed for determining the state of an inline filter. The differential pressure indicator determines the pressure drop on either side of a filter through its 1/8″ female NPT pressure connections, and relates the value to one of three zones: clean (green), change (yellow), or dirty (red). The Series PFG2 is perfectly suited for filter applications, line loss, valve drop, and many other differential pressure applications where a simple indicator is needed. The direction of process flow is indicated on the dial, with the arrow pointing to the low pressure port. The PFG2 can be connected in-line through the side process connections, but can also be directly mounted through the outlet/inlet.

Retail price from $98.5

The Series MP Mini-Photohelic® Differential Pressure Switch/Gage combines the time proven Minihelic® II differential pressure gage with two SPDT switching set points. The Mini-Photohelic® switch/gage is designed to measure and control positive, negative, or differential pressures consisting of non-combustible and non-corrosive gases. Gage reading is independent of switch operation. Switching status is visible by LED indicators located on the front and rear of the gage. Set points are adjusted with push buttons on the back of the unit.

Retail price from $501.3

Using solid state technology, the Series Photohelic 3000MR/3000MRS Photohelic® Switch/Gages combine the functions of a precise, highly repeatable differential pressure switch with a large easy-to-read analog pressure gage employing the durable, time-proven Magnehelic® gage design. Switch setting is easy to adjust with large external knobs on the gage face. Gage reading is unaffected by switch operation – will indicate accurately even if power is interrupted. Solid state design now results in greatly reduced size and weight. Units can be flush mounted or surface mounted with hardware supplied. 3000MR models employ versatile electromechanical relays with gold over silver contacts – ideal for dry circuits. For applications requiring high cycle rates, choose 3000MRS models with SPST (N.O.) solid state relays. All models provide both low and high limit control and include 18-inch (45 cm) cable assemblies for electrical connections.

Retail price from $636.5

The Series 1211 Slack Tube® Manometer is as accurate as the finest laboratory “U° gages, but is designed to roll up compactly for easy carrying. These manometers cover a wide range of pressure readings from 4-0-4 inches up to 60-0-60 inches.

The Model 1212 Gas Pressure Kit comes supplied with a 1211-16 Slack Tube® Manometer, carrying case, necessary tubing, and connection fittings for checking gas pressures in virtually all gas appliances. See the Support Library tab for Safety Data Sheets.

Retail price from $148,6

Dwyer® Series 100 Durablock® Solid Plastic Portable Manometers are precision instruments in inclined and vertical (well-type) styles for the measurement of static pressure, vacuum or differential pressure. To assure the accuracy required in instruments of this type, all machining of bores and wells is to the highest standards of precision backed by Dwyer’s years of experience in the fabrication of acrylic instruments.

Retail price from $737,35

Dwyer® Flex-Tube® U-Tube Manometers combine the inherent accuracy of the simple “U” Tube with the durability of tough, long-lasting plastic construction. These inexpensive manometers measure positive, negative and differential pressures. Columns are of .375″ O.D. flexible and shatter proof clear butyrate tubing. They are easily accessible for cleaning. Indicating tube is backed by white scale channel to provide maximum color contrast. Scales are extruded high impact polystyrene plastic, formed to hold columns in perfect alignment. Stark white scales have graduations and numbers silkscreen-printed in black for maximum legibility.

Retail price from $63,45

Series Mark II Molded Manometers are of the inclined and inclined-vertical types. The curved inclined-vertical tube of the Model 25 gage provides higher ranges with more easily read increments at low readings. The Model 25 is excellent for general purpose work. The Model 40 inclined gage provides linear calibration and excellent resolution throughout its range. The Model 40 is ideally suited for air velocity and air filter gage applications. Both gage types are capable of pressure measurements above and below atmospheric as well as differential pressure measurements. Included with each Mark II manometer are two tubing connectors for 1/8″ pipe or sheet metal ducts, two mounting screws, 1 ounce bottle of indicating fluid, red and green pointer flags and complete instructions.

Retail price from $57,8

Our Series LPG4 2.5″ Low Pressure Gage offers top of the line performance and accuracy for pressure and vacuum applications up to and including 160 in w.c. The LPG4 is constructed from a single beryllium-copper diaphragm affixed to a precision-machined brass plate. This innovative design, together with a high-precision, milled-teeth brass movement and nickel-silver pinion and bearing surface, provide the user with a top of the line low pressure instrument.

Retail price from $62,1

The Series DPG-200 Digital Pressure Gage has a precise ±0.25% full scale accuracy. The 4 digit digital display will reduce the potential for errors in readings by eliminating parallax error commonly produced with analog gages. The DPG-200 is packaged in a durable extruded aluminum case designed to meet NEMA 4X (IP66). The unit is powered by 12-24 VDC/VAC and contains two alarm set points along with a 4-20 mA process output. A four-button keypad allows easy access to features. These features include backlight, peak and valley, auto zero and conversion of the pressure units.

Retail price from $518,95

The Series DPG Digital Pressure Gages have a high ±0.25% or ±0.5% full-scale accuracy. The 4 digit digital display will reduce the potential for errors in readings by eliminating parallax error commonly produced with analog gages. Series DPG is battery powered and has an auto-shut off to conserve battery life. Battery life, on average, will last 2000 hours. A 4 button key pad allows easy access to features without the need to work through complex menus or difficult key combinations. These features include backlight, peak and valley, tare or auto zero and conversion of the pressure units.

Retail price from $295,35

The Series DPGA is the only economic digital pressure gage with selectable engineering units on the market. With its 1% accuracy and digital push-button zero, the DPGA is the perfect choice for digitally monitoring the pressures of air and compatible gases.

Retail price from $133,1

The Series DPGWB/DPGAB Pressure Gages offer 0.5% full scale accuracy in a rugged, easy-to-use unit at prices comparable to mechanical gages. The DPGWB stainless steel wetted material makes it suitable for a wide variety of liquids or gases. The gages feature user-selectable units of measure allowing one gage to be used for a variety of pressure scales. The DPGWB/DPGAB come with a protective rubber boot to protect against short drops and rough handling.

Retail price from $179,9

The Series 400 Air Velocity Meter offers the convenience of a dual purpose instrument with high accuracy and easy-to-read scales. It can be used to balance air conditioning systems, measure pressure drop across filters, and test fan and blower discharge and inlet pressures. Series 400 kits include a manometer, Pitot tube, necessary tubing and connectors, red gage fluid, and carrying case.

Retail price from $866,3

Bourdon tube pressure gauges anti-vibration version DS 2” (50mm)

Instruments designed for use on power units, pumps, hydro-cleaning machines, presses, engine compressors, turbines, diesel engines, chemical, petrochemical and refrigerating plants and on machines and equipment where pulsating pressures or mechanical vibrations are apparent. They can be used with gaseous or liquid media which do not corrode copper alloy and which do not have high viscosity or do not cristalize.

price by request

Bourdon tube “solid-front” pressure gauges NACE MR0175/ISO 15156-3 version DS 4”, 6” (100-150mm)

These instruments are built in conformity with the construction and safety specifications of EN 837-1/S3 e ASME B40.1. In case of leaks or break of the elastic element, the operator is protected by a solid separating wall placed on the front of the instrument and by the blow out back. They are usually used in the petrochemical industry; they are built to resist to the most severe conditions created by H2S and by the environment. The TIG welding between the case and the process socket, strengthens the instrument and assures a better tight in case of dampening fluid The advantages of filling the case of the instrument with a dampening fluid are: reduced pointer fluctuation, reduced wear of rotating parts of the movement when pulsant vibrations and pulsations occur. Moreover condensation and corrosive atmospheres which could damage the internal parts.

price by request

Bourdon tube pressure gauges anti-vibration version DS 2.5” (63mm)

Instruments designed for use on power units, pump, hydro-cleaning machines, presses, engine compressors, turbines, diesel engines, refrigerating plants and on machines and equipment where pulsating pressures or mechanical vibrations are apparent. They can be used with gaseous or liquid media which do not corrode copper alloy and which do not have high viscosity or do not cristalize.

price by request

Sanitary pressure gauges DS 2.5”, 4” (63-100mm)

These instruments are designed for Sanitary, Food Process and Pharmaceutical Industries in compliance with standard n.74-06 of 3-A (Sanitary Standards Symbol Administrative Council). The absence of interstices and the mirror finishing of the components assure the best hygiene. The combination of pressure gauge and diaphragm seal allow to reduce the inner volumes and temperature error.

To reduce the effects of severe working conditions like vibrations and pulsations, the instruments can be filled.

price by request

Bourdon tube pressure gauges anti-vibration heavy duty version DS 4” (100mm)

Instruments designed for use on power units, pumps, hydro-cleaning machines, presses, engine compressors, turbines, diesel engines, chemical, petrochemical and refrigerating plants and on machines and equipment where pulsating pressures or mechanical vibrations are apparent. They can be used with gaseous or liquid media which do not corrode copper alloy and which do not have high viscosity or do not cristalize.

price by request

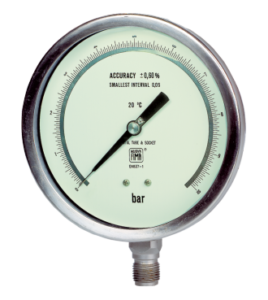

Bourdon tube test gauges all stainless steel construction class 0,6% DS 6” (150mm)

These instruments have been designed for laboratories, instrument testing or recalibration facilities and in other applications where accuracy and repeatability are of primary importance. Thay can be used with fluids or gasses that do not have high viscosity and do not cristallize. The wetted parts in AISI 316L permits to use them in worse working conditions determined by aggressive ambients or process fluids. Upon request we can supply the calibration certificate issued by an Internationally recognized laboratory of ACCREDIA (Ex S.I.T. – Italian Calibration Service).

price by request

Bourdon tube “solid-front” pressure gauges turret case DS 4.5” (125 mm)

These instruments are built in conformity with the construction and safety specifications of ASME B40.1.

In case of leaks or break of the elastic element the operator is protected by a stainless steel safety cell solid front and by the blow-out back. They are usually used in the chemical, petrochemical industries and in conventional power plants. The TIG welding between the safety cell and the process socket strengthens the instrument and assures a better tight in case of dampening fluid The advantages of filling the case of the instrument with a dampening fluid are: reduced pointer fluctuation, reduced wear of rotating parts of the movement when pulsant vibrations and pulsations occur. Moreover condensation and corrosive atmospheres which could damage the internal parts.

price by request

Bourdon tube test gauges all stainless steel construction, “solid-front” class 0,6% DS 6” (150mm)

These instruments have been designed for laboratories, instrument testing or recalibration facilities and in other applications where accuracy and repeatability are of primary importance. These intruments have a solid separating wall in stainless steel, placed between the dial and the elastic element and an integral blow out back that is released from the case whenever a pressure is created inside the case, due to leaks or accidental ruptures of the elastic element. Thay can be used with fluids or gasses that do not have high viscosity and do not cristallize. The wetted parts in AISI 316L permits to use them in worse working conditions determined by aggressive ambients or process fluids. Upon request we can supply the calibration certificate issued by an Internationally recognized laboratory of ACCREDIA (Ex S.I.T. – Italian Calibration Service).

price by request